The Manufacturing Process of bondo fiberglass resin in boats

Bondo fiberglass resin is used in many applications, but it is especially useful in boat construction and repair. The manufacturing process of bondo fiberglass resin is a complex process that requires attention to detail.

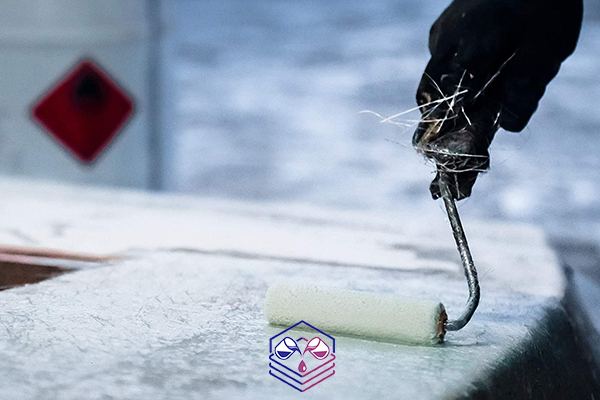

First, a mold of the boat is created using fiberglass cloth, chopped strand mat, polyester resin, and a release agent. This mold will be used to form the shape of the boat. The fiberglass cloth is woven together and then saturated with polyester resin. The chopped strand mat is then added on top of the cloth to strengthen it and provide additional stability. Once the polyester resin is cured, it is removed from the mold and the release agent helps with the separation of the mold from the final product.

Next, the fiber glass bondo is added to the cured fiberglass part. Bondo fiberglass resin is a mixture of polyester resin and chopped strand mat that are combined in a specific ratio. This ratio helps provide additional strength and durability to the part, as well as helps prevent cracking or breaking. After the bondo fiberglass resin is applied, it must be left to cure before it can be sanded and painted.

Finally, the boat is ready to be taken out on the water. Before this happens, however, a coat of gel coat must be applied to protect the surface of the boat and ensure a smooth finish. Gel coat also helps maintain the color and texture of the boat for an extended period of time.

Bondo fiberglass resin has become a popular choice among boat builders due to its high strength, durability, and low cost. Through careful consideration and meticulous attention to detail, this manufacturing process creates products that are both aesthetically pleasing and structurally sound.

In addition to being strong and durable, fiber glass bondo provides good insulation for boats, making them more energy-efficient when operating in colder temperatures. Furthermore, fiber glass bondo provides good UV resistance which means the boats will not lose their colour over time due to sun exposure. Moreover, fiber glass bondo is lightweight which makes it easier for boats to move through the water without dragging excess weight around with them. The use of fiber glass bondo also offers superior corrosion resistance compared to other materials which makes it ideal for boats since they may have contact with salt water. Lastly, fiber glass bondo is easy to repair if it does become damaged; another reason why it’s so popular amongst boatbuilders.

Fiber glass bondo can be formed into different shapes, allowing boatbuilders to create intricate designs without worrying about structural integrity. Also, fiber glass bondo has excellent adhesion qualities, allowing it to easily stick to most surfaces without any additional preparation. Furthermore, fiber glass bondo is self-leveling, meaning there’s no need to worry about inconsistencies or lumps when applying it. Because fiber glass bondo sets quickly, repairs can be done quickly and efficiently in comparison to other types of resin. Additionally, fiber glass bondo is resistant to solvents, oils, alkalis and acids, which make it suitable for most marine environments. Finally, fiber glass bondo is relatively inexpensive compared to other types of resins, making it an accessible option for most boatbuilders.

The Distribution of bondo fiberglass resin for boats

Bondo fiberglass resin is one of the most widely used materials in boat manufacturing, thanks to its strength and versatility. It is an extremely popular choice for boat repair and construction, due to its unique properties and ease of use. But before you can start using this material, you need to know where to get it.

In most cases, boat builders will source their bondo fiberglass resin directly from a distributor. This is the most convenient and cost-effective option, as they can easily compare different suppliers and order in bulk. Many major distributors also provide custom solutions that are tailored to specific requirements.

Retailer of bondo fiberglass resin

Online retailers are also a great resource for bondo fiberglass resin, as they often have the widest selection at competitive prices. However, when shopping online, it’s important to ensure that the supplier has a solid reputation and is providing quality products.

Local stores can also be a great place to purchase bondo fiberglass resin for boats. These shops are often knowledgeable about their products and can offer helpful advice about the best type of resin for your needs. Additionally, many local stores also offer installation services if you don’t feel comfortable installing it yourself.

Finally, if you can’t find what you need in store or online, you may need to contact a manufacturer directly. While this will likely involve more upfront costs, you’ll benefit from having access to higher-grade products with customized specifications. Plus, working directly with a manufacturer also provides peace of mind that you are getting quality products every time.

No matter which route you choose, it’s important to do your research and make sure that you’re getting the best quality product for your money. Fiber glass bondo is a powerful material that requires the right combination of knowledge and technique to be used correctly, so make sure to take the time to find the right supplier and distributor.

Fiber glass bondo should not be confused with fiberglass resin, as each type of material offers different benefits and applications. Fiberglass resin is much easier to apply than fiber glass bondo but doesn’t offer the same level of durability. Fiber glass bondo is much more difficult to work with but offers better protection against water damage and wear and tear. When purchasing fiber glass bondo, pay attention to the instructions and application instructions given by the manufacturer to ensure proper usage. You may even want to consider hiring a professional installer to make sure everything goes smoothly. Ultimately, fiber glass bondo offers unbeatable protection against water damage and wear and tear while also being easy to apply—it just takes a bit more patience and effort!

The Advantages of bondo fiberglass resin Over Other Materials

Bondo fiberglass resin is a popular material used in boat manufacturing and repair due to its advantages over other materials. Bondo fiberglass resin provides a smooth, durable, and corrosion-resistant finish for boat hulls and decks. It is also lightweight, allowing for easy application and removal of the material. Bondo fiberglass resin is an affordable and long lasting material that can be easily molded and shaped to fit any type of boat.

One of the main advantages of bondo fiberglass resin is its strength. The resin bonds extremely well to the fiberglass fabric and provides a waterproof seal that won’t crack or break down over time. This strong bond ensures a durable and secure connection between the resin and fiberglass fabric which prevents water and other substances from entering the boat’s interior.

Bondo fiberglass resin adhesive

Bondo fiberglass resin also has excellent adhesion qualities, meaning it will adhere to almost any surface with ease. This makes it ideal for both repairs and new construction since it can be applied quickly without having to sand or prime the surface first. Additionally, bondo fiberglass resin is resistant to UV rays and chemicals, meaning it can be used outdoors without fear of discoloration or breakdown over time.

Finally, fiber glass bondo is simple to work with and can be found in any local hardware store. All you need is the correct type of resin and hardener, plus the necessary tools and materials to complete the job. This makes it convenient to find and purchase the supplies you need to repair or build a boat with bondo fiberglass resin.

دیدگاه شما با موفقیت ثبت شد.