The Advantages of fibreglass gel coat Over Other Materials

Fibreglass gel coat has a number of advantages over other materials when it comes to manufacturing and using boats. Fibreglass gel coat is more durable than most other materials, making it the perfect material for the manufacture and repair of boats. The durability of this material is essential for those looking for a long lasting boat that will be able to withstand even the harshest elements.

Additionally, fibreglass gel coat is relatively inexpensive compared to other materials, making it a more cost-effective choice for boat manufacturers. Fibreglass gel coat is also more resistant to environmental damage and corrosion, making it an ideal choice for boats used in marine environments. Furthermore, it is easier to work with than other materials, making it simpler to install and customize boat hulls or other boat parts.

Finally, fibreglass gel coat provides excellent aesthetic qualities, making it an ideal choice for boat manufacturers who are looking to make their boats look sleek and stylish. The glossy finish of the gel coat creates a stunning visual appeal, making it a popular choice among boat owners who want to make their boat stand out from the crowd.

Fibreglass gel coat usage

Fibreglass gel coat can be used to achieve a variety of colors, allowing boat manufacturers to create unique designs and patterns on the surface of their boats. Moreover, fibreglass gel coat is lightweight, so it won’t add too much additional weight onto your boat, which is beneficial if you’re looking to travel long distances. Lastly, because fibreglass gel coat is UV resistant, it won’t fade easily due to exposure to sunlight, allowing you to maintain its original appearance for years to come. In summary, these are just some of the many benefits that come with using fibreglass gel coat as opposed to other materials for the sales, manufacturing and distribution of fiberglass resin.

Not only does it have outstanding durability and weather resistance, but it also offers superior aesthetics and versatility when it comes to creating attractive custom designs. Furthermore, its light weight ensures that you won’t have to worry about adding extra pounds to your boat. Finally, since it is UV resistant, you don’t have to worry about the color fading away in no time at all. With all these advantages, it’s no surprise why fibreglass gel coat is becoming increasingly popular among both professionals and hobbyists alike.

Sales of fibreglass gel coat

Fibreglass gel coat is the outermost layer of protection and the final finish used to coat fibreglass products, such as boats. It provides a protective coating that helps keep the boat’s surface looking new and in excellent condition. Fibreglass gel coat is also used to repair existing fibreglass surfaces by filling in dents and other damage.

When shopping for fibreglass gel coat, there are a few important factors to consider, such as its compatibility with the existing fibreglass surface, how thick it needs to be, and the amount of coverage that is required. There are a variety of options available on the market, ranging from DIY kits for home use to professional grade options for industrial applications. It is important to ensure that you purchase the right product for your needs.

There are several suppliers of fibreglass gel coat available both online and in stores. Many suppliers also offer custom colors and finishes, allowing you to create a unique look for your boat or other fibreglass project. Prices for these products can vary significantly depending on the quality, size, and finish of the product. Be sure to shop around to get the best price possible.

fibreglass gel coat products

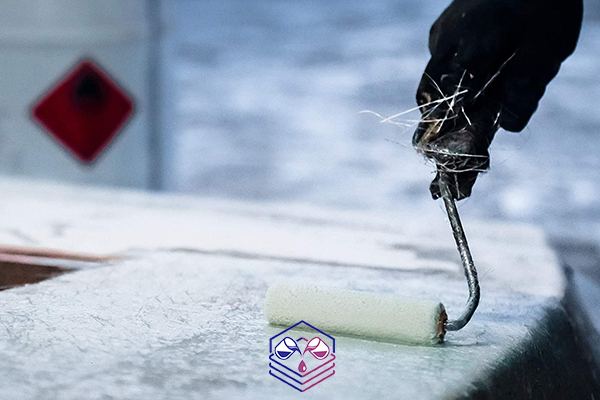

If you need help choosing the right product, many suppliers will provide technical advice and support to ensure you make an informed decision. Additionally, some suppliers may provide samples so that you can test the product before making a purchase. Once you have purchased the correct fibreglass gel coat, be sure to read all instructions carefully before applying it. Applying too much or too little may cause permanent damage to the fibreglass surface. To avoid this issue, always apply thin coats until you reach the desired thickness and smoothness. If applying multiple coats, remember to wait for each one to dry completely before applying the next one. Taking your time during application will ensure the end result is beautiful and long-lasting.

When storing unused fibreglass gel coat, be sure to seal the container tightly and store in a cool, dark place away from direct sunlight. Always follow manufacturer’s instructions for proper disposal of any leftover material. In addition to using fibre glass gelcoat on boats, it can also be used to restore furniture, countertops and other objects made from fibreglass or composite materials. Since it dries quickly and creates a durable finish, fibreglass gelcoat is often preferred over traditional paint or lacquer when refinishing objects made from fibreglass. For larger projects such as refinishing entire boats, it is recommended to hire a professional who has experience in applying fibreglass gelcoat properly. Doing so will guarantee the job is done correctly and safely.

When working with fibreglass gel coat, it is important to wear safety equipment such as goggles, gloves and protective clothing. This will help prevent any exposure to harsh chemicals or dust particles. As mentioned earlier, applying too much or too little of the gel coat can result in permanent damage to the surface, so take care when measuring and mixing your solution. Prior to applying the gel coat, it is necessary to sand and clean the surface thoroughly to ensure maximum adhesion. Lastly, once the gel coat has been applied, allow it to dry completely before exposing it to water or heavy usage. With careful preparation and application, fibreglass gel coat can create a lasting and attractive finish on any fibreglass surface.

shipping fibreglass gel coat

When it comes to shipping fibreglass gel coat, the most important factor is to ensure that the gel coat is securely packed and protected during transport. The gel coat should be wrapped in protective material such as bubble wrap and placed in a sturdy box to prevent any damage. It is also important to choose the right shipping service to ensure that the fibreglass gel coat reaches its destination in a timely manner and in the same condition it was sent. Additionally, customers should be aware of any special requirements for the delivery service they are using. For instance, if a customer is shipping fibreglass gel coat across international borders, it is essential to check the rules for importing and exporting such materials. By doing this, customers can be sure that their gel coat arrives safely and on time.

If there is any damage to the gel coat upon arrival, it’s important to contact the shipper immediately so that you can get a replacement or receive compensation for any loss or damage. Fibreglass gel coat can also be bought from retail outlets or online stores, depending on what type of product you’re looking for and what price range you’re comfortable with. In some cases, manufacturers may even offer direct sales where you can purchase products directly from them instead of going through a third-party retailer. Finally, when purchasing fibreglass gel coat, always make sure that you get it from a reputable supplier who offers quality products and provides good customer service. This way, you’ll have peace of mind knowing that your purchase will be long-lasting and effective.

Additionally, fibreglass gel coat works best when applied correctly according to the manufacturer’s instructions. Therefore, customers should pay close attention to the instructions provided by the supplier before beginning the application process. Applying too much fibreglass gel coat or not allowing enough curing time could result in cracking or blistering of the surface. Furthermore, it’s important to know that fibreglass gel coat does not adhere well to surfaces that are already painted. Therefore, it’s essential to apply a primer before beginning the application process. Another thing to keep in mind is that excessive exposure to UV light can cause yellowing or fading of fibreglass gel coat over time. To avoid this, try to keep the area covered when not being used. Lastly, it’s vital to use all safety measures while handling and applying fibreglass gel coat since it contains solvents and strong chemicals.

Always wear gloves, goggles, and masks when working with fibreglass gel coat to protect yourself from inhalation hazards. Additionally, when cutting fibreglass gel coat sheets into smaller pieces for smaller applications, use a sharp blade and protective gloves to prevent cuts or scratches. Before storing unused sheets of fibreglass gel coat, make sure to remove excess air from the packaging and store in a cool, dry place away from moisture. When sanding down excess fibreglass gel coat, start off with coarse grit sandpaper then move up to finer grits until you reach desired smoothness. Finally, to increase durability and longevity of fibreglass gel coat surfaces, it’s important to finish with a clear topcoat for extra protection against UV rays, abrasions, and dirt buildup.

Price of fibreglass gel coat in boats

When it comes to choosing the best material for your boat, you should consider the price of fiberglass gel coat. Fiberglass gel coat is a popular choice for boat owners due to its durability and low cost. In fact, fiber glass bondo is a more economical choice than other types of materials, such as polyester resins.

Fiberglass gel coat is available in a variety of prices depending on the quality of the product and the type of boat being built. Generally speaking, the price of a gallon of fibreglass gel coat will be anywhere between $15 to $50. It is important to keep in mind that the higher-end products can be expensive, but they will offer superior performance and protection.

When purchasing fiberglass gel coat, you should also take into consideration any additional costs associated with the product, such as shipping fees and labor costs. Labor costs vary greatly depending on the project and size of the boat, so it is important to budget accordingly. Additionally, if the gel coat needs to be shipped, there will be an additional fee for delivery.

Overall, fiberglass gel coat is an affordable and durable material for boat owners. When considering the price of this product for your boat, it is important to factor in all associated costs. This way, you can make sure you are getting the best deal possible for your boat.

If you are looking to save money, then one option is to purchase fiberglass bondo instead of fibreglass gel coat. Bondo requires less sanding after application, making it cheaper than gel coat. However, fiberglass bondo may not be able to provide the same level of protection or longevity as fibreglass gel coat. Another way to save money when purchasing these products is to purchase them in bulk. Many suppliers offer discounts for bulk orders, which can result in substantial savings when buying larger amounts of fiber glass bondo or fibreglass gel coat. Lastly, shopping around for different suppliers and comparing their prices may help you find the best deals on these products. Doing research and shopping around can help you find suppliers who offer better prices or better customer service, which could result in lower costs overall.

When applying fiberglass bondo or fibreglass gel coat, it is important to follow the instructions carefully. Taking shortcuts while applying the product could lead to poor results and costly repairs later on. Similarly, it is important to prepare the surface correctly prior to applying either of these materials. Surfaces must be cleaned thoroughly, free of dirt and grease, before applying either fiberglass bondo or fibreglass gel coat. Applying both of these materials over surfaces that have not been prepped correctly can lead to inferior results and a shorter lifespan of the product. Once applied, both materials need time to cure properly before use in order for optimal results. Finally, whether using fiber glass bondo or fibreglass gel coat, it is always beneficial to wear protective gear while applying either material. Protective gloves and masks should be used while working with either material, especially when using strong solvents or chemical cleaners.

Your comment submitted.