The Versatility of Polyester Resin

Polyester resin is a synthetic thermosetting polymer that has a wide range of applications in various industries. It is created by the reaction between a saturated diacid and a diol, producing a polymer that is highly resistant to water, chemicals, and heat. This material is used to produce a variety of products, from boats and car bodies to household items such as shower stalls and countertops.

- The Versatility of Polyester Resin

- Properties and Applications of Polyester Resin

- Advantages of Using Polyester Resin in Manufacturing

- Sustainability of Polyester Resin and its Impact on the Environment

- Advances in Polyester Resin Technology

- Growing Demand for Polyester Resin in Construction and Infrastructure

- Polyester Resin in the Automotive Industry: Lightweight and Durable Components

- Marine Applications of Polyester Resin: Corrosion-Resistant and High-Strength Materials

- Polyester Resin in Aerospace: High-Performance and Precise Components

- Medical Applications of Polyester Resin: Biocompatible and Versatile Materials

- Consumer Products Made from Polyester Resin: Durability and Affordability

- Sports and Recreation Applications of Polyester Resin: High-Performance and Lightweight Equipment

- Challenges of Working with Polyester Resin: Safety Concerns and Hazards

- Future Applications and Developments in Polyester Resin Technology

Properties and Applications of Polyester Resin

One of the key advantages of polyester resin is its versatility. It can be easily modified with fillers, dyes, and additives to create a wide range of customized products. This material can be used to create lightweight, durable, and corrosion-resistant parts, making it an ideal choice for applications in the marine, automotive, and aerospace industries. In addition, polyester resin can be molded into complex shapes, allowing manufacturers to produce intricate and precise components.

Advantages of Using Polyester Resin in Manufacturing

Another advantage of polyester resin is its sustainability. Unlike other types of plastics, polyester resin can be recycled and reused. This reduces waste and minimizes the impact on the environment. Moreover, polyester resin is made from readily available raw materials, such as petroleum, which makes it a cost-effective material for large-scale production.

Sustainability of Polyester Resin and its Impact on the Environment

Despite its many advantages, polyester resin also has some drawbacks. It can emit harmful volatile organic compounds (VOCs) during the curing process, which can be harmful to human health and the environment. To mitigate this issue, manufacturers have developed low-VOC and zero-VOC formulations of polyester resin that minimize the emission of harmful gases.

Polyester resin is a versatile and sustainable material that has revolutionized the manufacturing industry. Its unique properties make it an ideal choice for a wide range of applications, from high-performance sports equipment to everyday household items. As research and development continue, it is likely that polyester resin will continue to play an increasingly important role in modern manufacturing.

Advances in Polyester Resin Technology

Over the years, advances in technology have led to the development of new formulations of polyester resin with improved properties and performance. For example, one type of polyester resin called vinyl ester resin has better resistance to chemicals and UV light than traditional polyester resin. Another type, known as hybrid polyester resin, is a blend of different polymers that combines the best properties of each.

Growing Demand for Polyester Resin in Construction and Infrastructure

In recent years, there has been a growing demand for polyester resin in the construction and infrastructure sectors. This is due to its versatility, durability, and ability to withstand harsh environmental conditions. Polyester resin is used to make a variety of construction products, such as pipes, tanks, and panels, as well as in infrastructure projects such as bridges and tunnels.

Polyester Resin in the Automotive Industry: Lightweight and Durable Components

Polyester resin is widely used in the automotive industry to produce lightweight and durable components such as bumpers, body panels, and spoilers. These components are molded into complex shapes that are difficult to achieve with traditional metal manufacturing methods. Polyester resin is also resistant to corrosion, making it an ideal material for parts that are exposed to the elements.

Marine Applications of Polyester Resin: Corrosion-Resistant and High-Strength Materials

Polyester resin is a popular choice for marine applications due to its resistance to corrosion and water damage. It is used to make a wide range of marine products, such as boats, kayaks, and water tanks. Polyester resin is also used in the construction of marinas and docks, where its high-strength properties are essential for withstanding the constant forces of waves and currents.

Polyester Resin in Aerospace: High-Performance and Precise Components

In the aerospace industry, polyester resin is used to produce high-performance and precise components such as engine parts, wings, and fuselages. The lightweight and strong properties of polyester resin make it an ideal material for these applications. In addition, the ability to mold polyester resin into complex shapes allows manufacturers to create aerodynamic designs that improve the efficiency of the aircraft.

Medical Applications of Polyester Resin: Biocompatible and Versatile Materials

Polyester resin is finding growing applications in the medical industry due to its biocompatible properties. It can be used to create implants, prosthetics, and other medical devices that are safe and effective for patients. In addition, the versatility of polyester resin allows for customization of these devices to fit individual patients’ needs.

Consumer Products Made from Polyester Resin: Durability and Affordability

Polyester resin is widely used in consumer products such as shower stalls, bathtubs, and countertops due to its durability and affordability. It is a cost-effective material for mass production of these items, and its resistance to water damage and staining makes it ideal for use in bathrooms and kitchens.

Sports and Recreation Applications of Polyester Resin: High-Performance and Lightweight Equipment

Polyester resin is used to produce high-performance and lightweight sports equipment such as surfboards, skis, and snowboards. The durability and strength of polyester resin make it ideal for use in these applications, as well as the ability to mold it into complex shapes to improve the aerodynamics of the equipment.

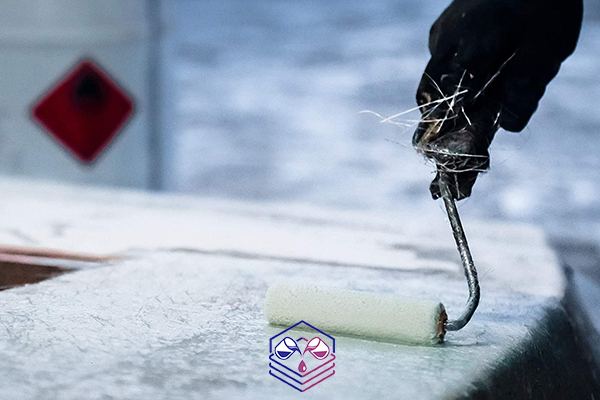

Challenges of Working with Polyester Resin: Safety Concerns and Hazards

Despite its many advantages, working with polyester resin can present safety concerns and hazards for workers. Exposure to harmful chemicals and dust particles during the manufacturing process can lead to respiratory problems and other health issues. Proper safety measures, such as protective equipment and proper ventilation, must be taken to ensure the safety of workers.

Future Applications and Developments in Polyester Resin Technology

The use of polyester resin is expected to continue growing in the coming years, as new applications and developments in technology are discovered. Researchers are working on new formulations of polyester resin that are even more durable, sustainable, and customizable than ever before. As the demand for more versatile and sustainable materials continues to rise, polyester resin is poised to play a leading role in the future of manufacturing.

Your comment submitted.