fiberglass-polyester-resinPolyester or poly resin or fiberglass resin is another resin product that can sometimes be mistaken again with other types of resin that are available in the market. Polyester resin can sometimes be mistaken so therefore consulting experts regarding your resin has always been recommended but polyester or poly resin or fiberglass resin can be compared with other resin for a clear understanding on what to expect from the goods and the needs of your resin procurement so that a better understanding can always serve a good purpose. We’re going to take a closer look at polyester resin and terms represents among all the substances that can be used in a variety of ways in buildings of boats and model making as well as a production of ponds and swimming pools therefore polyester or poly resin or fiberglass resin can be used to create fiber composites as well as different thermoplastics. The mechanic and the chemical properties of resin into the final project impacts the cross-linking process while curing. We will also take a look at the properties of polyester resin because it is specific to fiberglass which is a synthetic resin that has different properties depending on the application it can have different outcomes. There are a lot of advantages to using polyester resin because it has a high saturation effect and once it is fully cured it is weather resistant water resistant and it can be a very strong material to be used in different industries.

Polyester resin application

Amongst other several uses of polyester or poly resin or fiberglass resin For home building and construction materials because of its Great Looks That it Gifts to any surrounding environment and therefore it is used in architecture as well as Interior design and other artworks, it’s your ability has made it be able to use as in aircrafts and vehicles in the Marine industry as well so it is very reliable as well as it can be used to be used as packaging materials and appliances from furniture and specially outdoor items to composite materials and fiberglass resin. Polyester resin is of course better at standing heat and wearing and cracking it is also erosion resistant so it can boost and deterioration in the environment and in the chemistry of the resin itself and the polyester resin is less durable than the other resin it’s is better suited for short-term fixes and that it cost even less than other resin so that will be there for the ultimate durability and formulation prerequisites are that the polyester resin one could be taking closer look at the places that it can be best used.

Sales and manufacturers of fiberglass polyester resin

The sales and supplies for fiberglass polyester resin with us is consistent and your manufacturing process of your fiberglass polyester resin will never be interrupted with our supplies of fiberglass polyester resin . The cost of your fiberglass polyester resin will be at its most efficient when it is low on raw materials. The best prices of fiberglass polyester resin from support and the sales team can be enquired. We entered the best prices of fiberglass polyester resin and the best quality of fiberglass polyester resin. We highly recommend you to reach out to us for fiberglass polyester resin and any other resin for that matter and get the best deals on your fiberglass polyester resin.

Benefits of using polyester resin over other resin

With polyester resin you can choose from a variety of reinforcement and material can fabric so that you can actually add resistance to your product. Other resin can also be combined with a filament that will make the serve carbon fiber break so therefore both service in their own particular niche where they will have to serve their best at their chemical level. Well, of course to polyester resin is less expensive and can be used in greater and larger amounts compared to prices of the other resin , however, we will provide you with the best prices regardless of the type of resin that you require so therefore you can be sure that you are actually making your purchase from the factory as we provide you with information.

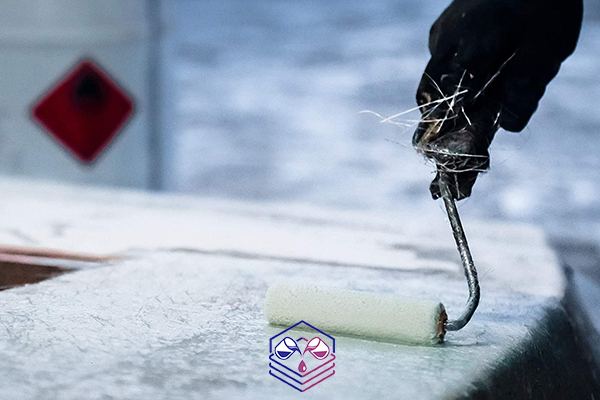

The time for polyester can be adjusted to your needs so definitely we can alter the amount of the hardener and the blending in the liquid resin. It can be directed from the manufacturer what kind of a solution that you require and that it will best suit you. From 1% to 2.5% you can add when it comes to other resin and from the total components. If it is not cured correctly can become weak so that the end result does not suit. Polyester resin of course is an acceptable resistance and it has a relatively low shrinkage compared to other material or resin and that it is sufficient to resistance in aging. Weather and get any sort of harsh conditions that he can’t be put through so therefore it is the best when it comes to certain products that it needs to be fitting in.

Polyester resin properties

About the mechanical properties of polyester resin ,it falls above other resin which is the stronger in many ways and that other material can also be used with surfaces while polyester resin cost less but cannot adhere to smooth surfaces like metal or glass so therefore it is highly recommended to be using other material. If you are dealing with such surfaces and that the polyester resin produces toxic fumes which is also linger and it’s best to work with resins outside. The resin can be used inside even though it is still requires its own ventilation as well as safety measures that we have already advised you on many different sectors. In boat building much can be replaced with polyester resin. Resin is more water resistant. For any form of these two the best quality of the material with the ratio can be provided you so that you can get your best polyester or poly resin or fiberglass resin.

Polyester or poly resin or fiberglass resin

Regardless of whether you’re using resin or polyester resin they can both be using the same way that can actually worked with fiberglass smooth surfaces and that the chemical bonds within the structure will allow its perfect combination with fiberglass and it is used in both making as well as and all kinds of material that uses fiberglass inside and that these composite fiberglass resin polyesters in the marine industry as well are also in common with the fiberglass and it’s used. Polyester resin is the most widely used system in the Marine industry and in workboats of course because it also works with the composite material of fiberglass.

Unsaturated polyester resin is a thermostat capable of being cured from the liquid to the solid form and is subject to the right conditions so that you can endure the toughest conditions and last long. The principal type of polyester resin in standard laminating system in the isophthalic and orthophthalic resin that is used and that what is used as in standard economy by many people and the other is now preferred material of the industry such as the marine and the superior water resistance is desirable for these types of Industries. It is important to note does it cost of different reasons depend on the use case and therefore they have their own favorable use cases so therefore most probably surfaces are very vicious and there are actually pale colored. They are transparent and they can be added with color of liquids consisting of dissolution of the polyester and the amount of a steering is up to 50% that makes the resin easier what is vital function of enabling directions to cure from its liquid to solid form.

It is once again important to mention that amongst a lot of different types of resins, it is very important to seek consultancy for the type of need for your industry and be able to purchase the particular solvent that is required to meet your needs at the craft you have at hand and be able to resolve.

دیدگاه شما با موفقیت ثبت شد.