Most polyester resins are vicious and faint and include a solution of polyester in a monomer, usually styrene. Adding styrene in amounts above 50% reduces viscosity and makes resin easier to use. On the other hand, the key role of styrene is to make it possible to cook resin by creating a network between the ester sections without producing by-products. Therefore, these resins do not require pressure to be molded, and contact or low-Isophthalic Resin resins are prescribed. Polyester resins have a limited storage time and become gel or harden over a long period of time.

What is the Isophthalic Resin?

Unsaturated polyester resins dissolve in an active solvent (diluent). This active solvent is mainly a styrene monomer, which performs two functions in unsaturated polyester resin. First, it reduces the viscosity of the resin. And secondly, this monomer contains a double bond that also acts as a networking agent.

And by connecting polyester molecules from their unsaturated points, it makes the resin a hard lattice. Networking reaction in unsaturated polyester resins by adding a small amount of catalyst. It starts like an organic peroxides.

These materials decompose into free radicals due to heat or an accelerator, and the resin solidifies due to the chemical interactions between the solvent and the unsaturated bonds in the unsaturated polyester. Therefore, a small amount of inhibitor is often added during resin production to reduce the rate of gel depletion.

How to Identify Quality Yellow Isophthalic Resin?

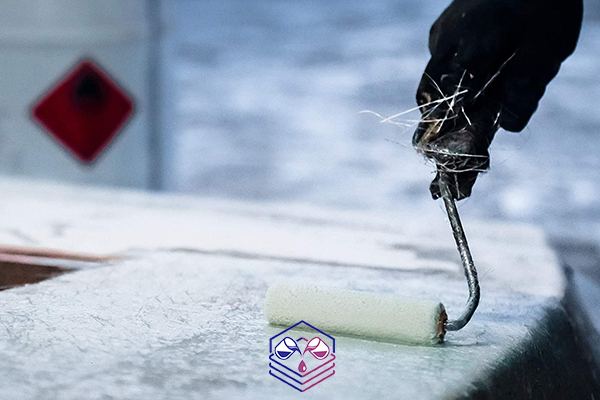

Any resin mixture must be carefully prepared before molding. The resin and all additives must be carefully mixed until all the components are evenly distributed throughout the mixture before adding the catalyst. This shaking and shaking must be done carefully because the entry of any air molecule into the resin mixture affects the quality of the final mold.

This is especially important when the resin is laminated with layers of reinforcing material and there is a possibility of air bubbles forming between the layers, as these bubbles can weaken the structure. Another important point is to determine the exact amount of catalyst and accelerator and add it to the resin mixture to better control the polymerization reaction and obtain the material with the best specifications. Too much catalyst greatly shortens the feeling time, and too little will cause the resin to not cook properly.

Staining the resin mixture is done with the help of pigments or pigment paste. It is very important to choose a suitable pigment, even if the pigment is only 3% of the weight of the resin added to the mixture. Because the use of inappropriate pigmentation affects the cooking reaction and allows the destruction of the final laminate. isophthalic resin price, it is better to use colored doughs (isophthalic resin chemical properties) that are made for coloring resins.

Your comment submitted.